当社では、母体となるクロスエフェクトが長年培ってきた開発試作技術とリソースを最大限に活用して、

医療分野に特化したものづくりを行なっています。

精密な臓器モデルをはじめ、実験機器や医療機器、メディカルイラストなど、

迅速なスピードで企画段階から社内で一貫して対応しています。

臓器シミュレーターを始めとする高品質なものづくり

-

01

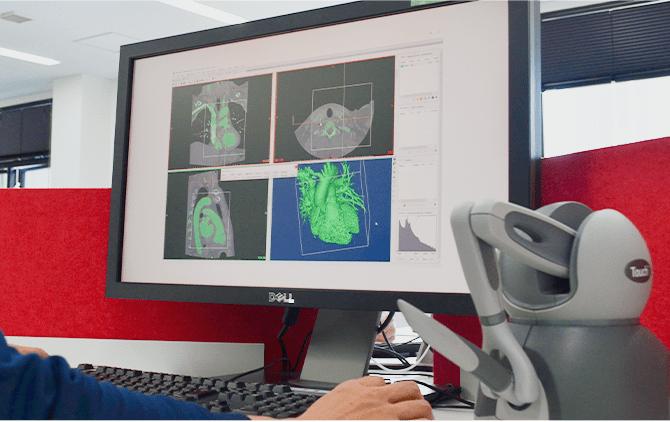

01生体データをもとにした

精密な製作が可能CTやMRI検査で得られたDICOM形式のデータをもとに、医療データ専任のスタッフが目的の部位を正確に抽出し、精密な3D臓器モデルを製作します。

-

02

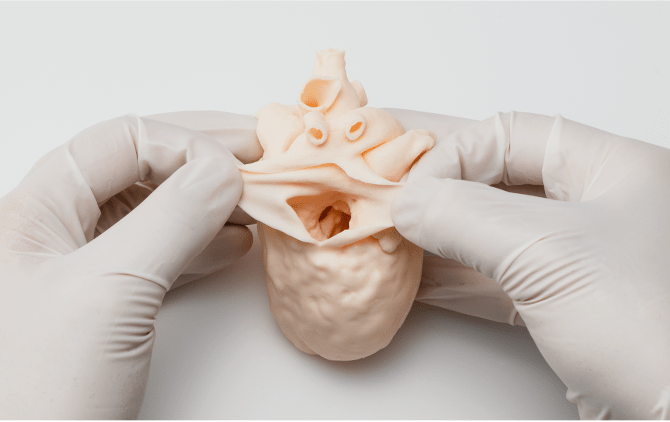

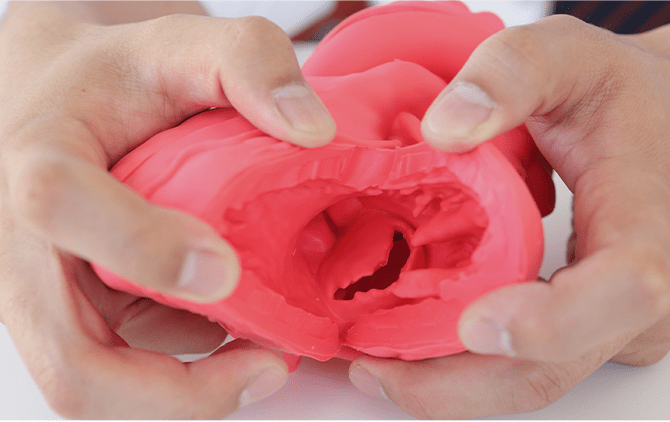

02より高い再現性で

質感と内部組織を実現実際にメスで切開したり、開口部を開いて内部を観察できるのは軟質樹脂ならでは。なかでも軟質精密ウェットモデルは、実際の組織の質感に極めて近いインク剤を採用し、より精度の高い内部組織を再現しました。当社では、仕様に適した樹脂を選定し、ご要望に応じたモデルを製作します。

-

03

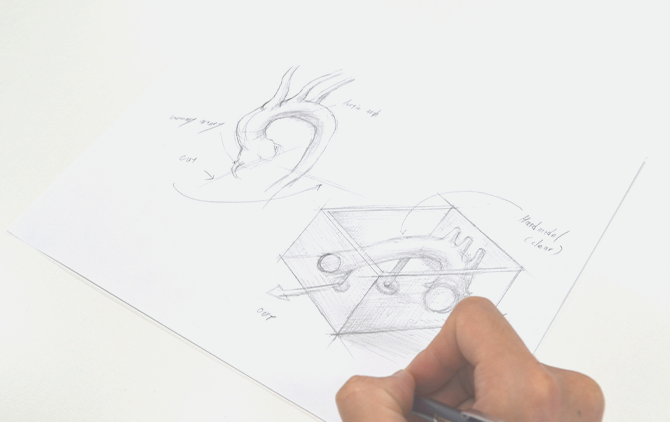

03ゼロからのものづくりが可能

当社には、お客様のまだ明確ではないイメージから詳細なご要望にいたるまで、より速く具現化するノウハウと実績があります。まだ世の中にはない医療機器のデザインや試作、製作が困難に思われる臓器モデルのご依頼など、ぜひ当社にお任せください。

-

04

04社内一貫体制が可能にする

速さと品質の高さ当社では、3Dデータの作成からモデルの製作まで、すべてのプロセスを京都にある本社内で行なっています。社内一貫体制によって、よりスピーディーに、よりご満足いただける質の高い製品をお届けします。

クロスメディカルの

保有技術

-

01

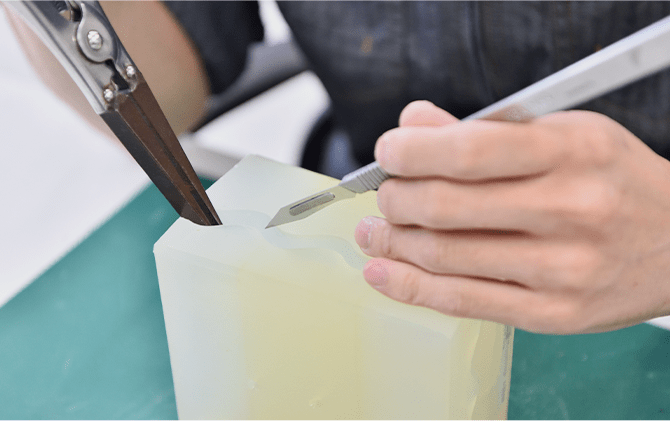

01最適な材料と工法をご提案

当社ではお客様のご要望に応じて、工法を選択します。主に真空注型というシリコーン型を用いた成形方法でモデルを製作。透明樹脂や軟質樹脂など型に流し込む材料を変更することで、自由度の高いものづくりを可能にしています。

-

02

02特殊な技術が可能にする

内部構造の表現高速光造形技術とハイブリッド真空注型技術(特許取得)を駆使することで、心臓や血管などの空洞構造が存在する臓器の製作が可能。内部構造を生み出す特殊な技術は、より精度の高いモデルを製作する当社の強みのひとつです。

-

03

03人体組織に近似した新素材

「AquainGel®」での製作水を主成分とした「AquainGel®」で製作されたモデルは、生体に近似した粘弾性(硬さ/柔らかさ)、摩擦(滑り感)の再現が可能な為、カテーテルのシミュレーションや外科トレーニングなど幅広い用途にご使用いただけます。

クロスメディカルの「ものづくり」

当社では、医療現場のご要望をものづくりで解決したいという想いをもとに、4つの事業を展開しています。

-

術前の診断を補完する術前シミュレーター

患者様個々の生体データをもとに

製作する術前支援モデルは、

解剖学的な構造を把握できる医療機器です。

術前診断を補完するためにご活用いただけます。 -

ご要望の仕様で精密な3Dモデルに再現オーダーメイド臓器モデル

ご使用用途に応じてスタンダード臓器モデルを

カスタマイズできるほか、脳や肺、肝臓など

あらゆる部位の臓器モデルをオーダーメイドで

製作しています。 -

より実践的に活用できるスタンダード臓器モデル

生体データをもとに製作した臓器モデルは、

精巧な内部構造を実現。素材に軟らかい樹脂を採用しているため、

切る、縫う、曲げる、開くことができます。 -

開発試作の技術で、様々なソリューションを医療系ものづくり

医療や医学のクリエイティブなご要望に対して、

豊富なソリューションをご用意しています。